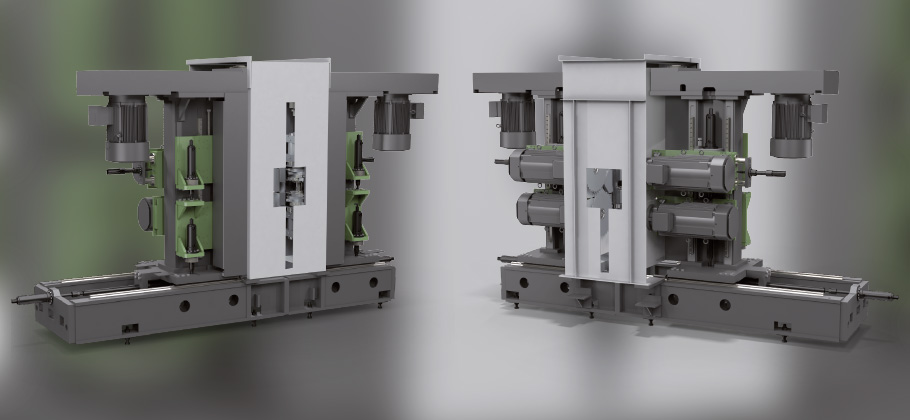

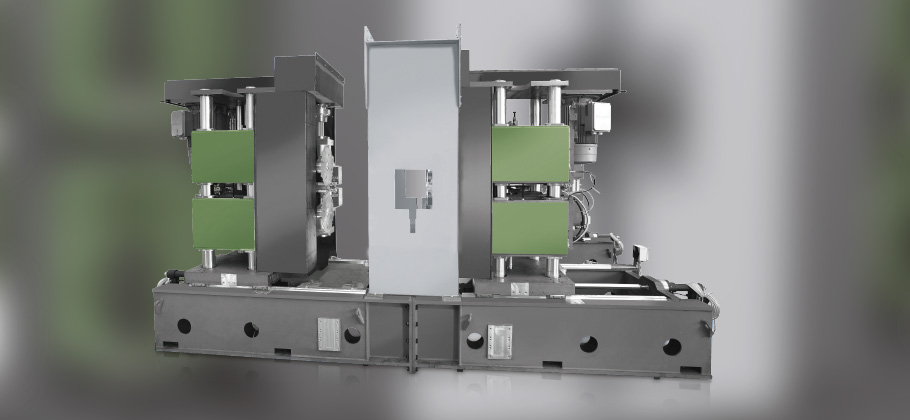

PROFILING AND SAW UNIT

PROFILING AND SAW UNIT FR 16

Profiling and sawing with one machine, for scan and set processing.

Profiling

Allows per side the profiling of one side board. Profiling with vertically arranged

profiling heads for variable position and width of the side board. The profiling

heads may be fitted for a variable chip length of up to 30mm with 2 or 4 knives

on the tool circumference.

For the production of pellet chips and for lumber without fibre tear out and extra-

ordinary long tool usage times the P-System heads, developed together with

LEUCO, will be used.

Sawing off

Up to 2 side boards per side may be sawn off from a log or 2-sided cant with the

double arbor circular saw module. In the standard version, the inner side board

thickness is fix set, using spacer rings. For a flexible thickness of the inner side

board an optional saw arbor with telescopic inner saw arbor is available. The

horizontal and vertical positioning of profiling heads and saw blades is done by

servo-hydraulic setworks.

Sliding platform for easy and safe access for tool change and maintenance.

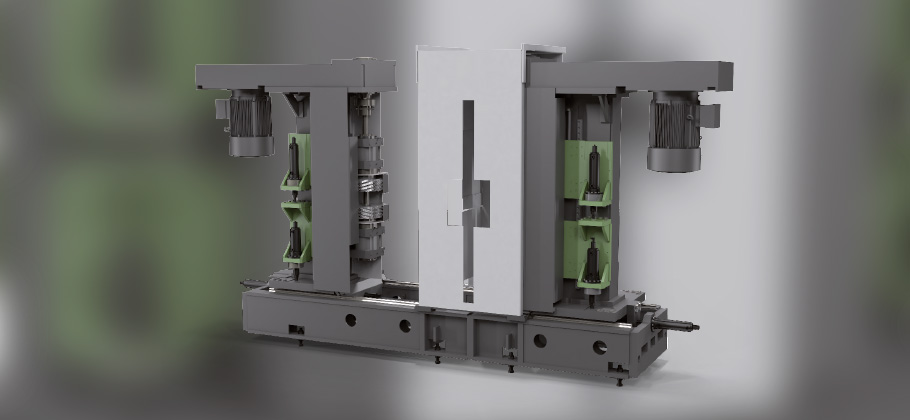

PROFILING UNIT FR 15 V

Profiling with vertically arranged profiling head, for variable position

and width of the side board

The FR 15 V profiling unit does the profiling of one side board per side. The

frequency controlled profiling is done with vertically arranged profiling heads.

The profiling heads may be fitted for a variable chip length of up to 30mm

with 2 or 4 knives on the tool circumference.

For the production of pellet chips and for lumber without fibre tear out and

extraordinary long tool usage times, the P-System heads, developed together

with LEUCO, will be used. The horizontal and vertical positioning of profiling

heads is done by precision servo-hydraulic setworks.

Sliding platform for easy and safe access for tool change and maintenance.

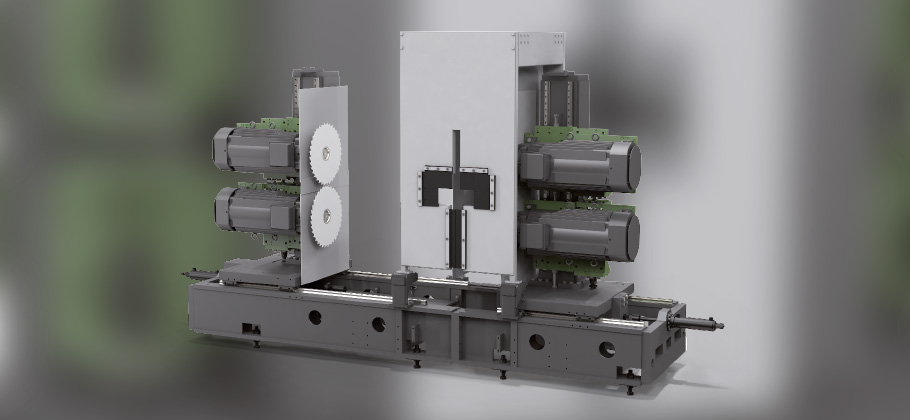

SAW UNIT FR 14

Double arbor circular saw for the sawing off of side boards

The FR 14 double arbor circular saw unit can saw up to 2 side boards per side

from a log or 2-sided cant. In the standard version, the inner side board thick-

ness is fixed, using spacer rings. For a flexible thickness, even of the inner side

board, an optional saw arbor with telescopic inner saw arbor is available.

The horizontal and vertical positioning of saw blades is done by servo-hydraulic

setworks.

Sliding platform for easy and safe access for tool change and maintenance.

PROFILING UNIT FR 15 H

Profiling with horizontally arranged profiling head, for variable

position and width of the side board

The profiling unit FR 15 H does the profiling of one side board per side. The profiling

is performed through the horizontal profiling heads. The profiling heads may be fitted

for a variable chip length of up to 30mm with 2 or 4 knives on the tool circumference.

For the production of pellet chips and for lumber without fibre tear out and extraordinary

long tool usage times, the P-System heads, developed together with LEUCO, will be used.

The horizontal and vertical positioning of profiling heads is done by precision servo-hydraulic

setworks.

Sliding platform for easy and safe access for tool change and maintenance.

The profiling unit FR 15 H can perform diagonal profiling of the boards, relative to the

transport level at full feed speed to achieve an even higher recovery.

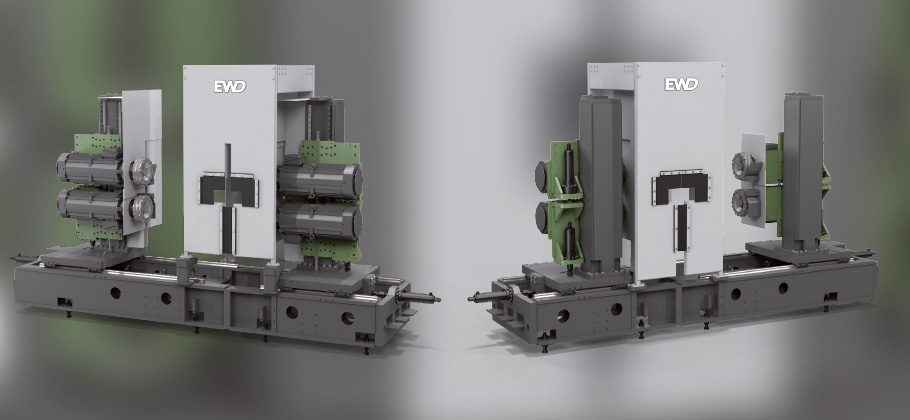

PROFILING UNIT FR 15 S

Profiling with vertically arranged profiling heads and preceding

notching saws

The pulp and paper industry requires for their process optimisation and the best paper

quality a high and homogenous chip quality. The use of preceding notching saws avoids

the generation of “comma” chips. The profiling chips produced by the FR 15 S reach the

maximum chip quality achievable for this process.