LOG BANDSAW TECHNOLOGY BY EWD

faster - more gentle - easier

more flexibility - more value yield- fewer operators

No other sawing process offers the flexibility and individual possibilities to convert

round logs into many different products as the Log Bandsaw Technology does.

- universal sawing applications

- economically feasible

- high degree of automation

- dynamic electric drive systems

- precise servo-hydraulic positioning systems

- modern scanning and optimisation process

- process reporting and visualisation

The modern EWD Log Bandsaw Technology makes the 1 operator

sawmill become reality.

The high degree of automation and a modern control stand allow one operator to

monitor besides the bandsaw headrig operation the automatic performance of edger

-optimizer, flitch cross cut saws and a circular resaw as well.

slanted 17°

- The loading of the logs onto the carriage is significantly faster due to the

easy transfer. - The quality of the sawn face of the log can be well seen.

- The transfer of the sawn lumber onto the discharge conveyor happens

fast, gentle and in a safe way. - Due to the slanted set-up, the lumber lands on the transfer conveyor

with the waney face up - As a result, the further processing of the lumber is easier.

KST Separating saw

- depending on the log length or the application the separation is done with or

without cross cut function - automatic separating and cross cutting

- with automatic or semi-automatic positioning

- input of dimensions via PC interface or predefined tables

- automatic positioning of the carriage EW2 for cross cutting

PF 19-1 chipper canter

The chipper canter PF 19 is used in Circular Saw or Reducer Bandsaw lines and also in

Profiling lines for chipping of two parallel faces on logs or cants. The width adjustment

of the chipper head supports is done by servo-hydraulic setworks.

- Straight knives and spiral knives chipper head with pre- or post-sawing segments

- precise servo-hydraulic positioning systems

- tool change position

- chips meet the high quality requirements of the pulp industry

- Motor mounting possible in two versions

1. laterally on the base frame

2. placed over the chipper head bearing

Chips

The produced chips meet the high quality requirements of the pulp industry.

Revolutions

The chipper head revolutions are controlled by a frequency converter as a function

of feed speed and desired chip lengths.

Straight knives / Spiral knives

Optionally, the chipper canter PF 19 can be fitted with either straight knives, spiral

knives or stepped knives heads.

The different head types are matched by the number of tools installed to the desired

speed range.

All heads are fitted with either pre- or post-sawing circular saw rings, depending on

the purpose.

EW2 Log bandsaw carriage

- Powerful and flexible

- highly dynamic electric drive system with a frequency converter-controlled

gear motor - drive up to 55 kW

- high setting speeds

- spacing of the headblocks and the log turners can be customised to individual

requirements. - high positioning accuracy and high setting speeds

- headblocks with servo-hydraulic setworks and independent adjustment of the dogs

- horizonatal dog adjustment 0 – 200 mm

- high accuracy (pulling of the lumber against the headblock)

- remote-controlled pressure of the dogs

- hardened, easily replacable dogs

- automatic carriage positioning

- specially laid, precision-ground tracks for precise guidance with 5-year warranty

EBB Log Bandsaw Module 1600, 1800

- many years of precise operation in outstanding EWD quality

- installation possibilities: single or tandem log bandsaw and 17° slanted

- forward and backward cut

- hydraulic EWD bandsaw strain system with fast reaction time and instantaneous

shock absorption for high precision - precise, servo-hydraulic positioning systems

- sawblade deviation detector

- tooth detector

- detection of cracks in sawblades

- blade guide with linear guide system, adjustable in height by servo-hydraulic

setworks - wheel bearings without bending stresses

- minimal bearing wear, highest precision and smooth running

- automatic blade cleaning and lubrication unit

- precision grinded, balances bandsaw wheels made of spheroid graphite iron

- inclination of the top wheel can be set by means of an electric motor

FBS FLYING BANDSAW

For very high demands on performance and sawing accuracy, we use the active

saw guide system FBS with intelligent magnets.

The advantages:

- Relieving the saw blade of stress through conventional pressure guides allows the

introduction of higher saw strain and higher saw speeds. - Exact guiding of the saw blade in the saw track by the magnetic forces of the FBS

technology enables significantly faster feed rates.

The results are

- constant accurate sizes

- notably higher production and recovery.

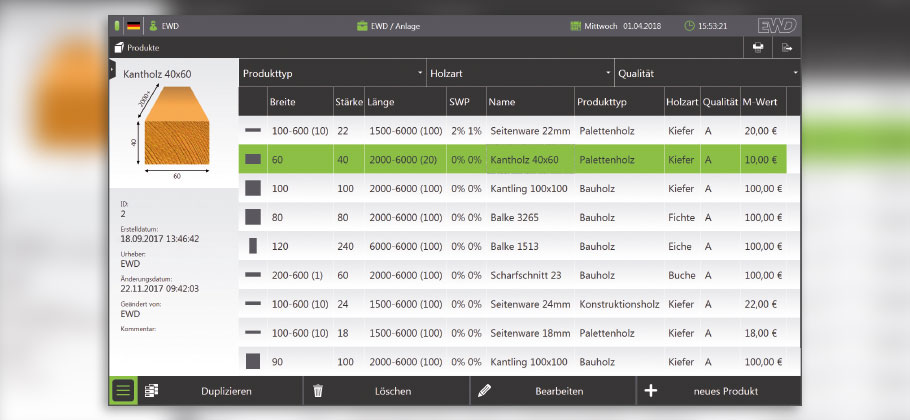

eWood

eWood is a comprehensive optimisation and application software from EWD. All

modern EWD sawlines and machines share the same eWood user interface.

The interface man – machine offers an intuitive and consistent user concept,

allowing effective use of the

- Most modern measuring technology

- Professional optimization and application software

In addition to solid and time-proven mechanical engineering,efficient system

controls are essential prerequisites for the high efficiency and yield of the EWD

Log Bandsaw.definition of

- flexible maintenance plans

- user management

- functionalities

- user-related

- data collection per day/month

- single log report

- export / print / eMail

- saved in SQL database

- graphic processing

Collectable data

- input volume

- output volume

- main products

- sideboards

- number

- work time

- break times / downtimes

Controls and Operation

- clear user interface with clear menu navigation

- constant display of information

- various automation possibilities

- display of sawing lines with camera system

- decentralised structure of the control system

- cutting pattern management

- data storage and management / optimisation of cutting pattern by PC

- visualisation of the plant functions

- remote maintenance, diagnostic and statistic functions

- export / print / eMail

- graphic processing