EDGER OPTIMIZER TECHNOLOGY COMBIMES

for boards, flitches and cants

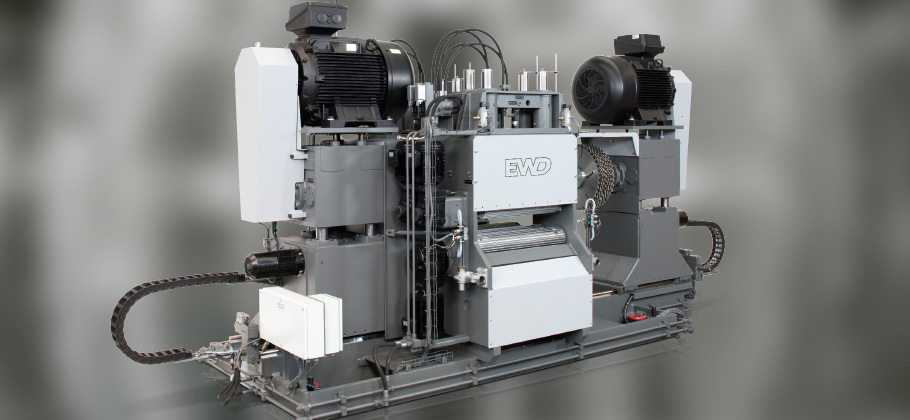

Universal edger optimizer and resaw system

The edger optimizer system Combimes provides steady performance class of

up to 24 boards per minute. Its robust design ensures superior production and

yield figures, even under tough conditions.

The Combimes can be used for a wide variety of production tasks thanks to

different models of edger and combination edger/resaw units available.

Depending on the mechanical design, the operator can turn the products at

his workplace, trim and enter quality information or lumber species.

Various configurations in the field of product manipulation and feeding enable

the user to find the most optimal installation for himself.

Partially automated with operation on the machine or automated with operation

from a cabin are decisive advantages.

Process

Depending on the mechanical design, the operator can turn the products at

his workplace, trim and enter quality information or lumber species. The

scanning takes place in the integrated cross transport with 2 dogs, with which

the products are then aligned and transferred directly to the longitudinal trans-

port in the saw.

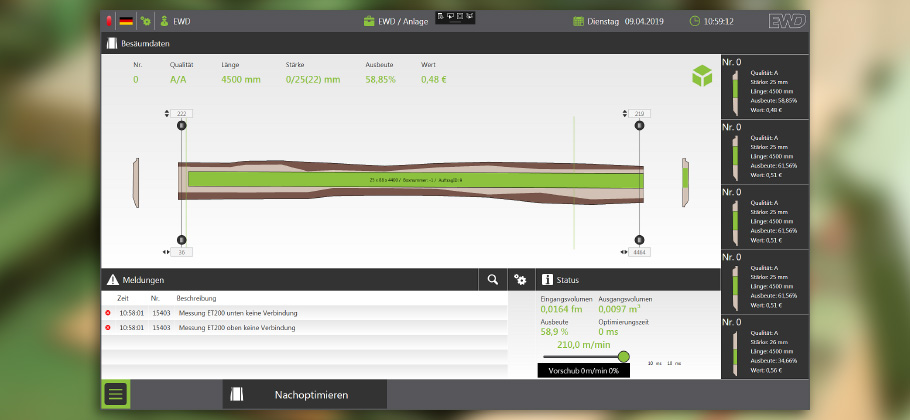

The scanning

The cross-sections of the products are scanned to determine the top surface

by means of laser triangulation from top. Depending on the design, products

with a thickness of up to 120 mm or 225 mm can be scanned.

When using single lasers, the distance and number of scan points can be

selected, from 13 lasers for 6 m workpiece length in the standard version

up to 25 lasers. Optionally, a laser scanner is available from bottom,

eliminating the need to turn the products.

Alternatively, the system can be equipped with a full contour scanning system

for special requirements.

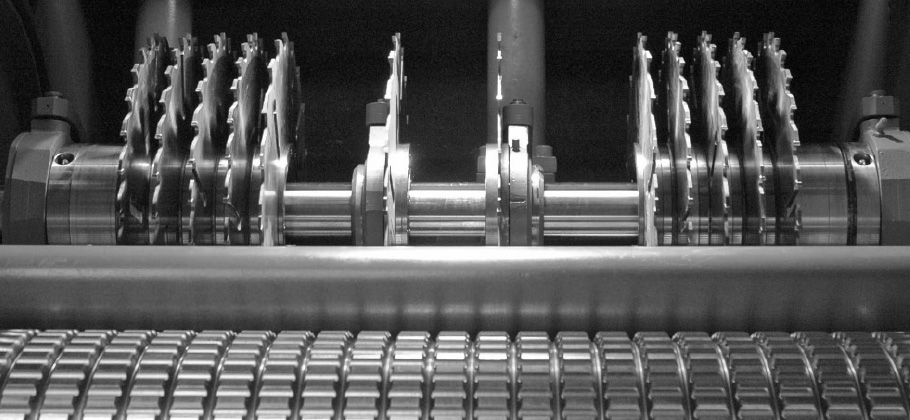

The mechanic

The chains of the measuring and depositing cross conveyor are controlled

independently with frequency converters for the defined transport of the

product with dogs and are positioned..The transport speed is selected

depending on the product thickness. Reflective photo eyes installed in the

feed table determine the approximate board length. Based on the result the

required active chain runs are selected.

The feed speed of the infeed chain adjusts itself automatically depending on

the lumber thickness and the number of saws cutting. The speed may be

limited or e.g. be reduced for winter operation.

All skewing and lifting movements of the infeed table are hydraulically

actuated.

Board manipulation

Before handing over to the infeed table, the products can be turned or rejected

with a hydraulically operated device, which at the same time serves as a slab

flap. At the partially automated trimming station, the boards are then usually

cut to the final length on the top end with the integrated 0-saw.

Further possibilities:

- End slab saw at approx. 3 m with ejection of the remaining piece

within the operation zone - Separating and end slab saw for board separation into 2 pieces or

discharge of remaining pices - Liftable and lowerable driven aligning rollers for manipulating heavy

products or for moving a separated board

For higher performance requirements, a separate board manipulation with

automatic functions can be installed in front of a Combimes. This board

manipulation is remote-controlled by the operator from a cabin. For reasons

of capacity, a faulty slab cutting to approximate length is usually made only

if necessary.

Wane-parallel sawing

With appropriate mechanisation with a product guide, thanks to the free

alignment possibilities of a Combimes system, fibre-parallel value wood

cuts can be made in 2 passes along the outer contour with residual piece

in the middle.